section-0a604e0

section-520b1b2

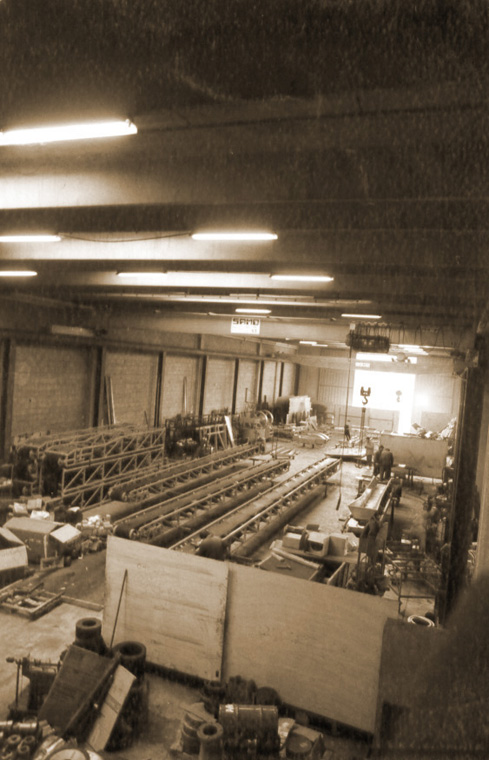

OMF occupies a covered area of 2,500 m2, has its own research and development department, technical department, sales department, administrative department, manufacturing unit and spare part warehouse.

Experience and continuous research have led the company to develop a complete range of machinery for the mining industry, the recycling of demolition waste material and the premixed concrete industry.

The OMF plant design follows the entire process of production and processing of aggregates, including feeding and pre-screening, crushing and screening, washing and recovery, transport and storage, classification and automation for both fixed and mobile structures, creating the best plant design solutions evaluated based on the characteristics of the raw material and product required.

Thanks to the R&D and technical departments, equipped with the most innovative 2D and 3D CAD design techniques, the best solutions can always be selected for each individual request and requirement from the customer.

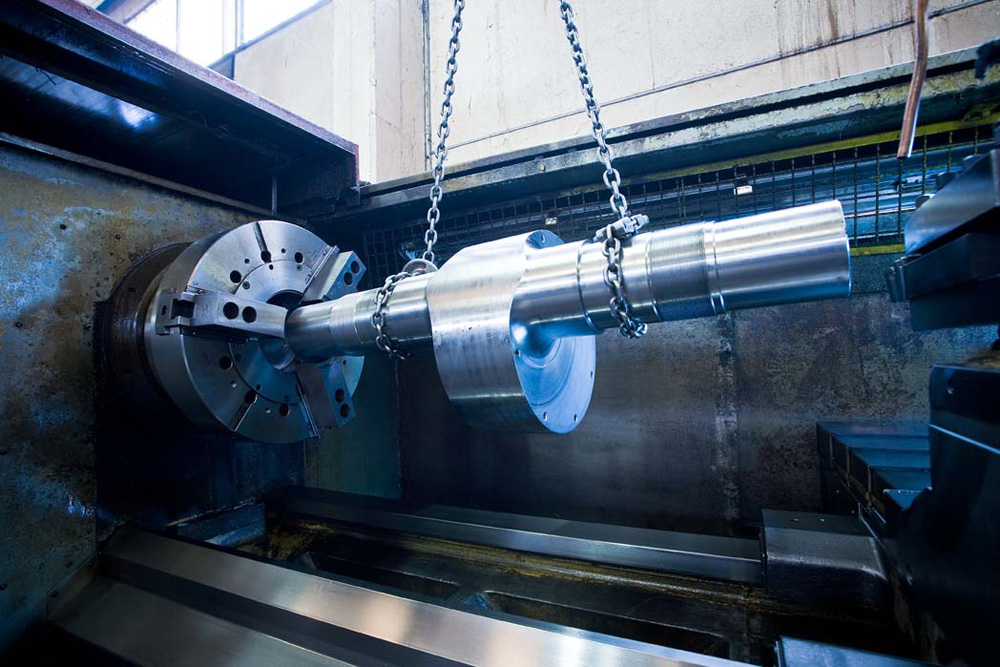

The production is fully controlled in all its phases up to commissioning and all the components are carefully chosen and controlled.

Being present on both a national and international level OMF has created and organised a new warehouse to quickly meet the demand for spare parts, minimising the downtime of equipment and machines sold all over the world.

section-2162c8d

The company OMF was founded in 1994.

It specialises in the design, manufacture and pre and post sale support of machinery and equipment for crushing, screening, washing, recovery and transport of aggregates.

Since its inception, the company has been committed to providing machinery and plants with high-value performance, durable, wear-resistant, safe and reliable, both in Italy and abroad with customers of major importance.

The quality of the machinery manufactured, their positioning during the design phase, the use of top quality components and the availability for project management, supervision, commissioning and maintenance, have made it possible for OMF to become an established and highly regarded organization both nationally and internationally.